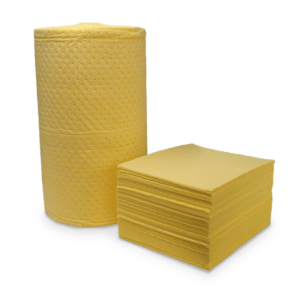

In the landscape of workplace safety, spill kits serve as essential guardians, poised to swiftly contain and mitigate spills of hazardous substances. However, the longevity and effectiveness of these kits are not solely determined by their initial quality; rather, they rely on consistent care and adherence to best practices.