Crystalline silica is a hazardous substance found in many individual materials including concrete, bricks, tiles, and engineered stone. Prolonged exposure to silica dust can lead to serious health conditions, including silicosis, lung cancer, and chronic obstructive pulmonary disease (COPD). As awareness of the dangers of silica exposure grows, governments and regulatory bodies have introduced stricter compliance measures to protect workers from its harmful effects.

What are the New Crystalline Silica Compliance Regulations?

In response to growing concerns over workplace silica exposure, new regulatory changes have been introduced across Australia. These changes include:

Lower Workplace Exposure Limits (WELs)

Regulatory agencies have significantly reduced the permissible exposure limit for respirable crystalline silica. The new threshold is designed to better protect workers from long-term health risks. In Australia, the exposure standard has been reduced to 0.05 mg/m3 over an eight-hour shift—a substantial drop from previous limits.

Mandatory Air Monitoring

Employers in high-risk industries are now required to conduct regular air monitoring to ensure compliance with exposure limits. This involves measuring silica dust levels in workplaces and keeping detailed records of monitoring results.

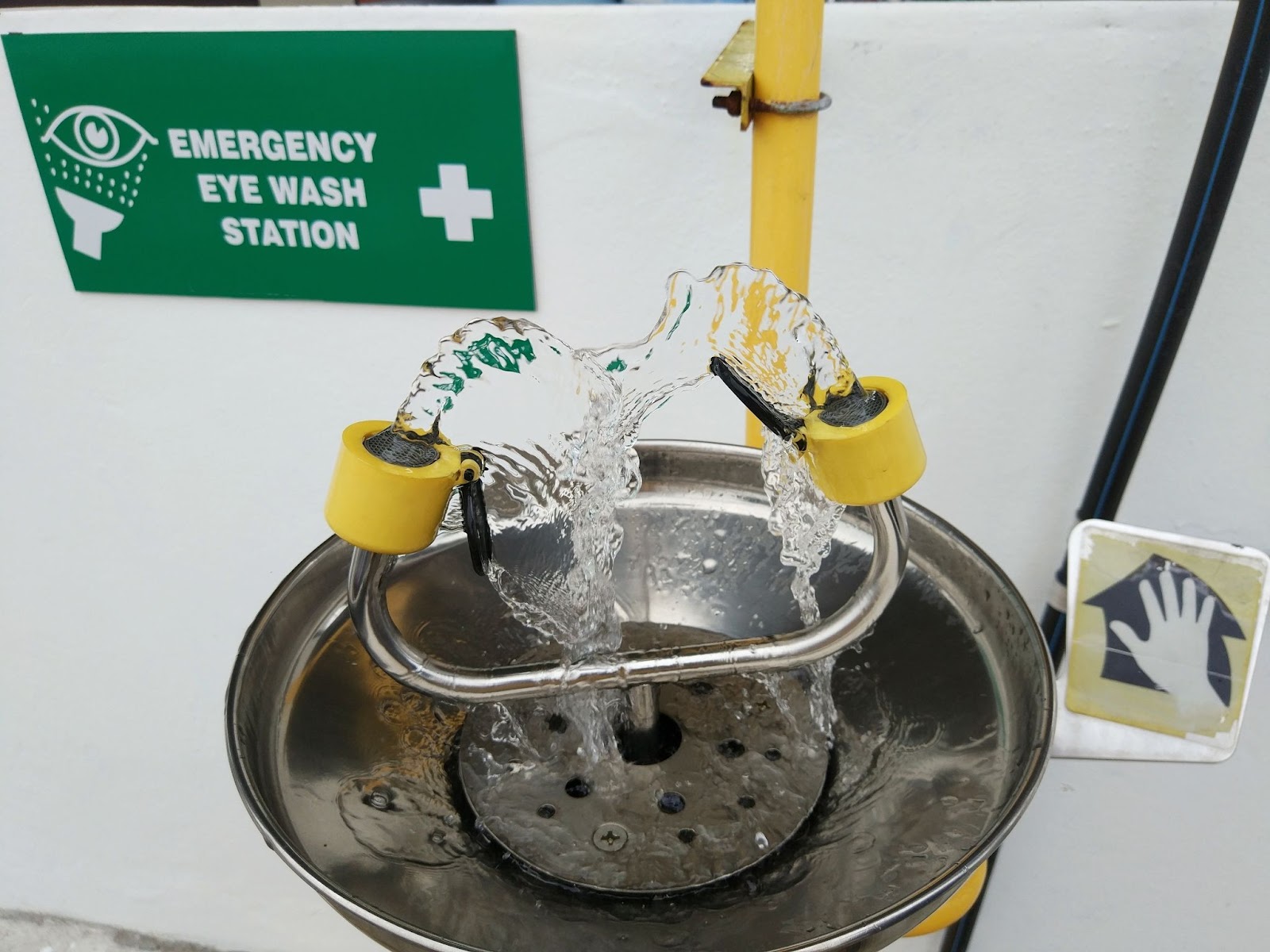

Stronger PPE and Ventilation Requirements

Businesses must now implement enhanced personal protective equipment (PPE) measures, including respirators with higher filtration ratings. Additionally, improved ventilation and dust suppression techniques must be incorporated into workplace environments to minimise airborne silica.

Prohibition on Certain High-Risk Materials

Some Australian states have introduced bans on high-silica engineered stone, particularly products that contain more than 40% crystalline silica. This is a significant shift for industries such as construction, manufacturing, and stonemasonry, requiring businesses to find safer alternatives.

Stricter Workplace Training and Documentation

Employers must now provide comprehensive silica safety training for workers, ensuring they understand the risks and best practices for protection. Detailed documentation of safety procedures, risk assessments, and control measures is also mandatory under new compliance guidelines.

Why Have These Changes Been Introduced?

The new silica regulations are a response to increasing cases of silicosis, a debilitating lung disease caused by inhaling silica dust. Silicosis has been described as the “new asbestos” due to its severe health consequences and the growing number of affected workers.

Key Reasons for the Regulatory Changes

- Rising Cases of Occupational Disease: The number of silicosis cases has surged, particularly among workers in the engineered stone industry.

- Scientific Research and Advocacy: Studies have shown that even low levels of silica exposure can cause long-term health issues.

- Industry-Wide Concern: Calls from health professionals, unions, and advocacy groups have pushed for stronger safety regulations.

- International Standards Alignment: Australia’s new regulations align more closely with global workplace health and safety standards, reducing legal and health risks for businesses.

What Does this Mean for Businesses?

Companies operating in industries that generate silica dust—such as construction, mining, and manufacturing—must take immediate action to comply with the new regulations. Non-compliance can result in severe penalties, including fines and business shutdowns, as well as increased liability for workplace injuries and illnesses.

Key Compliance Actions:

- Conduct workplace air monitoring and risk assessments.

- Upgrade PPE and dust suppression systems.

- Implement better ventilation and containment strategies.

- Train employees on silica safety and exposure prevention.

- Switch to compliant spill containment products that reduce silica risks.

Introducing EcoSorb Xtra: A Compliance-Ready Mineral Spill Solution

With the introduction of these new silica safety regulations, businesses must now rethink their choice of spill absorbents. Many traditional ‘kitty litter type’ mineral spill solutions contain high levels of crystalline silica, putting workers at risk of exposure if not used with caution and the necessary PPE.

Why Choose EcoSorb Xtra?

Ecospill’s EcoSorb Xtra is a heavy-duty mineral spill absorbent on the market that fully complies with the latest crystalline silica regulations. It provides an ultra-low dust solution for businesses seeking to protect their workers while maintaining workplace safety.

- Fast Absorption and Odour Reduction: Quickly absorbs spills while minimising unpleasant odours.

- Versatile Absorbency: Effectively soaks up oil-based, water-based, and aggressive chemical liquids including Hydrocarbons.

- Ideal for Windy Conditions: Heavy enough to resist displacement, making it a reliable spill barrier in outdoor and high-airflow environments.

- High-Performance Wicking Action: Leaves minimal residue for a cleaner surface post-spill.

- EPA Compliant & Safe Disposal: Passes USEPA 9095a Leachate Test, making it safe for landfill disposal (businesses should check local regulations for specific requirements).

Looking for a 100% Silica-Free Option?

In addition to EcoSorb Xtra, Ecospill also offers a range of organic absorbents that are naturally crystalline silica free, ensuring full compliance with the new regulations. These organic absorbent particulates provide a powerful, environmentally responsible option for hydrocarbon spill response, digestion, and worksite remediation.

Stay Ahead of the Regulations with Ecospill

It is important to take proactive steps to protect your workers, remain compliant, and improve workplace safety. By regularly reviewing your spill kits, and spill kit response training, you’re investing in a safer, cleaner, and more compliant future for your business.

To enquire about our latest organic and mineral absorbent solutions engineered for maximum environmental compliance and zero silica exposure, contact Ecospill for a complimentary workplace spill response assessment, or download our spill kit guide here.