Emergency Shower & Eyewash Testing Services

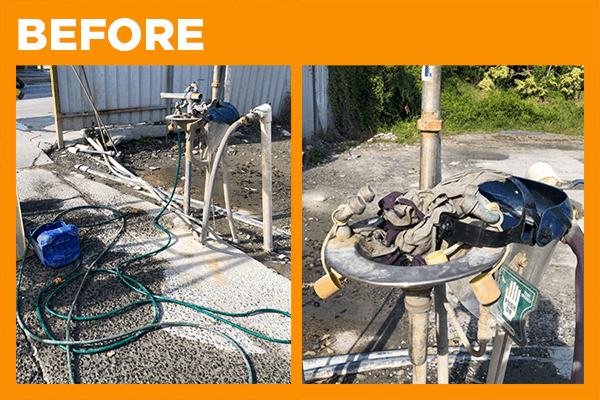

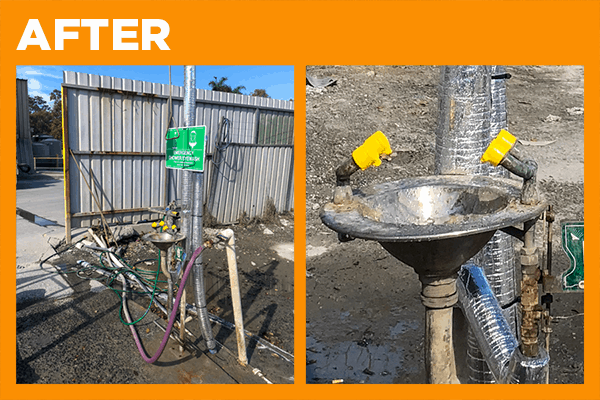

Did you know that more often than not, Emergency Showers and Eye Washes within the workplace may not be compliant with the Australian Standard? Our service technicians see many showers and eyewash stations left for long periods of time that have become unusable and unsafe. Some units don’t even deploy at all, and others shoot out brown flushing fluid that is far from eye-sight saving! Yet, emergency showers and eyewash units are designed to save lives, skin and eyes. The difference between a superficial exposure or significant chemical burn injury can be just seconds. So when it comes to emergency life-saving equipment, quite literally, every second counts. And if the units in your workplace don’t deploy like they should, that’s a risk not worth taking. To protect yourself and your staff, Ecospill offers Emergency Shower & Eyewash Testing Services.

Annual Inspections are Necessary

The Australian Standard governing Emergency Showers and Eye Wash Units mandates that all emergency units should be deployed weekly, and most importantly, testing annually (AS4775-2007 “Australian Standard Emergency EyeWash and Shower Equipment”. Sections 6.5, 6.5.2, 6.8, 7.3, 7.6, 8.6, 9.3, 9.6 11.2, 11.3). This is the only way to ensure that emergency units remain compliant and operational as front line emergency life-saving equipment. Ecospill is pleased to provide Annual Shower Inspections. Call us now on 1300 736 116 to book your inspection, and know that your equipment will work as it should.

What is included at our Annual Shower & Eyewash Inspections?

At the annual inspection, our qualified technician will look at the key components required for optimum performance as set out by the AS4775-2007 Australian Standard. Each unit will be thoroughly inspected checking that the location and signage are inline with the Standard. We also inspect the unit for signs of wear and corrosion. Each unit is deployed and the performance is recorded, noting water flow rates, temperature, spray dispersal, activation issues, functioning/malfunctioning parts and other benchmarks. A detailed report of the units conformance / non-conformance to the Standard is provided to the customer. For the most part, minor repairs and adjustments can be made at the initial inspection, without having to wait. Major repairs or replacement of units can be planned for a return visit.

Real Life Examples from our Annual Shower & Eye Wash Testing Inspections:

|

|

|

|

|

|

|

|